Wheel Block System

How do different types of wheel blocks compare in terms of load capacity?

DRS wheel block systems are essential components in systems that transport or move heavy equipment—cranes, transfer cars, monorails, presses, etc. Demag offers several wheel block series (LRS, DRS-M, DRS, RS, DWS) each tailored for different load capacities, environmental conditions, and performance requirements. Below is a comparison of the major types of Demag wheel blocks and how they differ in load capacity and related design trade-offs.

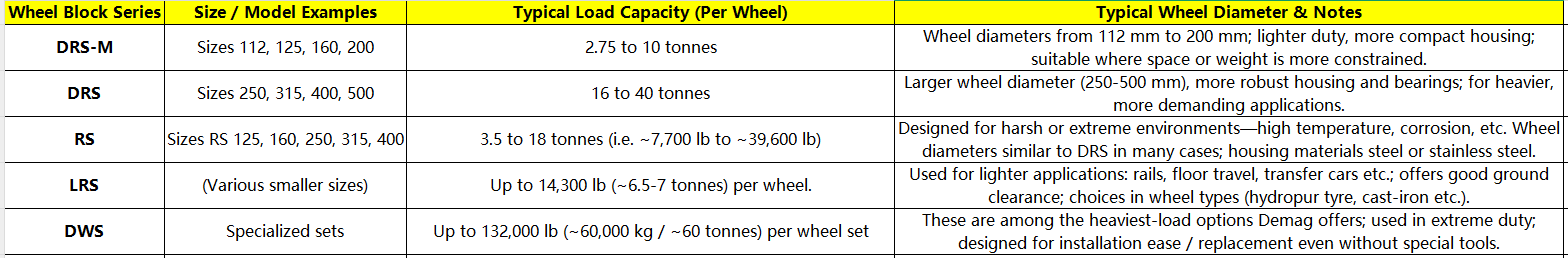

1. Key Demag Wheel Block Types & Their Capacity Ranges

These are among the heaviest-load options Demag offers; used in extreme duty; designed for installation ease / replacement even without special tools.

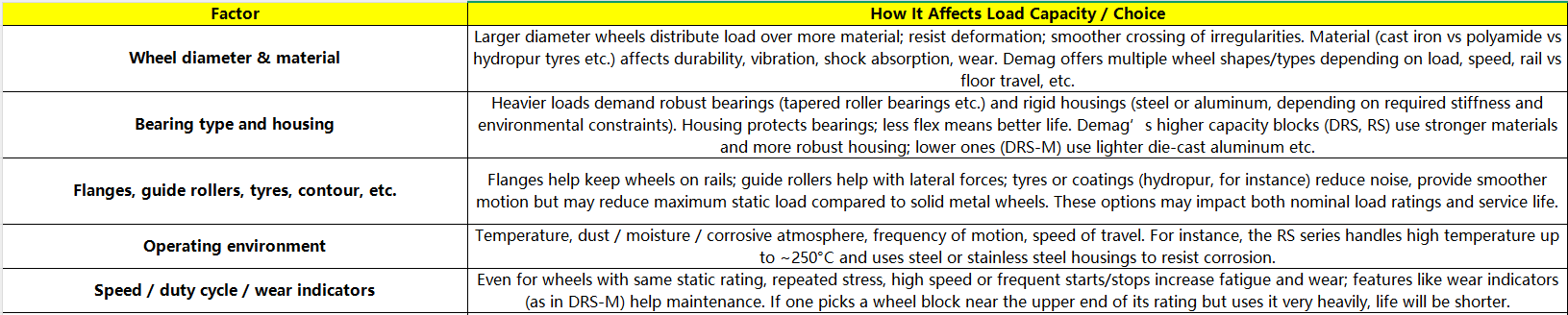

2. Design Trade-Offs & What Influences Capacity

Load capacity isn’t just a number; it’s determined by several interacting design and operational factors. Here are the things to consider:

3. Typical Use Cases & Matching Block Types

Here are examples of matching requirements with the appropriate wheel block type:

Light transferred loads, slower speeds, indoor applications → LRS or smaller DRS-M sizes. Good when budget, weight, and ground clearance are more constrained.

Moderate loads, more frequent travel, higher reliability needed → mid-range DRS-M (or small DRS) sizes.

Heavy loads, high duty cycles, structural rigidity, potential side loads / impact → full DRS series, possibly RS if environment harsh or temperature extremes.

Extreme loads / very heavy-duty / high temperature / chemical / abrasion → RS or DWS series depending on the capacity and environment.

4. Summary & Guidelines for Selection

If your load per wheel is < ~10 tonnes, chances are a DRS-M block will suffice, with savings in weight and possible cost.

For loads between ~16 to 40 tonnes, DRS blocks are more appropriate.

If you expect harsh environments (heat, corrosive materials, etc.), RS series (steel/stainless housing) may be needed even if your load isn’t maximal.

For ultra heavy loads or special conditions (very large travel spans, dynamic loads, extreme wear, etc.), consider DWS sets or specialised DRS/RS configurations.

Always factor in not just static load but dynamic loads, safety factors, frequency of use, speed, alignment, and maintainability.

Latest News & Blog

Key Considerations for Selecting Polyurethane Wheels for Electric Forklifts

11 May, 2023Polyurethane wheels are widely used in electrical forklifts because of their excellent durability, load-bearing capacity, and resistance to wear and tear. However, selecting the right wheels is crucia

Polyurethane Coated Wheels Solve Operational Challenges

11 May, 2023Polyurethane coated wheels provide industry-specific solutions for logistics, manufacturing, and specialized environments, enhancing efficiency, reducing costs, and protecting valuable assets.

How to Select and Install Forklift Wheel

11 May, 2023Selecting and installing polyurethane forklift wheels requires careful consideration of load capacity, floor conditions, operating environment, and the specific function of each wheel type. Proper installation involves safely lifting the forklift, removing old wheels, inspecting components, and securely fitting new wheels to manufacturer specifications.

Heavy Duty Polyurethane Wheel Manufacturers in China

11 May, 2023Philson is a leading heavy duty polyurethane wheel manufacturer, offering high-performance PU wheels with superior load capacity, wear resistance, and custom engineering for industrial applications.